- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-06-07 Origin: Site

Jaw crushers are essential machines in many industries, but do you know how they work? Understanding the key parts of a jaw crusher is crucial for efficient operation and long-lasting performance.

In this post, we’ll explain the parts of a jaw crusher and their functions. You’ll learn why each component is important and how they contribute to the overall crushing process.

The drive motor is essential for powering the jaw crusher. It connects to a reducer sheave that drives an eccentric shaft. The motor's role is to generate the energy needed for crushing. Once the flywheel is in motion, the motor only needs to provide the energy to keep it turning.

The flywheel generates momentum, allowing the crusher to run smoothly during operation. It helps maintain energy and balance, ensuring the crusher doesn't lose power between crushing cycles. By storing energy, it assists in the crushing action and reduces strain on the motor.

The eccentric shaft, also known as the pitman, is critical in generating crushing motion. As the shaft rotates, it creates an up-and-down movement. This motion drives the jaw plates, causing them to move and crush the material. It’s vital for transmitting energy from the motor to the crushing action.

Toggle plates convert the motion of the pitman into crushing force. They ensure the jaw moves back and forth, crushing the material between the jaws. In addition, toggle plates act as a safety mechanism. Shear bolts break when uncrushable material enters, protecting the rest of the crusher from damage.

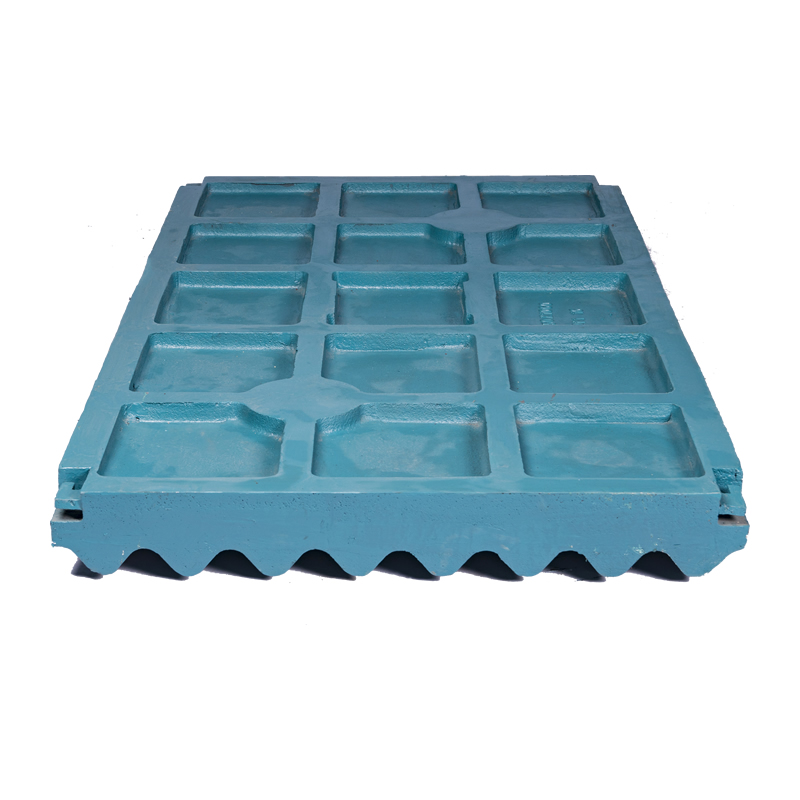

Jaw plates are typically made from high-strength materials like manganese steel. These plates are the primary surface for crushing materials. As they wear over time, they must be regularly replaced to maintain efficiency. The durability of jaw plates directly affects the crusher’s performance and longevity.

The frame is the jaw crusher’s core support structure. It holds all the other parts in place, ensuring the crusher operates efficiently. Frames are typically made from heavy-duty materials to withstand the crushing forces. The strength of the frame ensures the overall durability of the machine.

A jaw crusher is a powerful machine used in the first stage of material reduction. It uses two hardened steel jaws to crush materials by squeezing them together. The primary function of a jaw crusher is to reduce large rocks and ores into smaller, more manageable sizes.

Understanding the parts of a jaw crusher is key for efficient operation and maintenance. Each part plays a vital role in ensuring the crusher works smoothly and reliably.

Bearings support the eccentric shaft and enable smooth movement during operation. They ensure that the crusher operates efficiently with minimal friction. Jaw crushers typically use roller bearings, which require regular inspection and lubrication to maintain performance. Failure to maintain bearings can lead to costly repairs and downtime.

Cheek plates are located on the sides of the jaw crusher. Their primary role is to protect the crusher frame from wear and damage caused by the material being processed. They also help direct the material through the crushing chamber, ensuring that it moves toward the discharge area smoothly.

The retraction spring and screw rod system help stabilize the pitman and toggle plate during the crushing process. This mechanism prevents excessive movement and potential damage to other components. It ensures that the crushing action remains efficient and that the parts remain intact, even when uncrushable materials are encountered.

Proper lubrication is essential for ensuring that all moving parts of a jaw crusher function smoothly. There are several lubrication methods:

● Manual Grease: Applied manually through a grease gun at designated points.

● Grease Pots: Automatic grease feeders that provide consistent lubrication.

● Metering Pump: A more advanced system that controls grease distribution.

Regular lubrication helps reduce friction, extend the lifespan of parts, and improve overall crusher efficiency. Without it, components like bearings and the eccentric shaft could wear out prematurely.

Regular inspections are essential to keep your jaw crusher running smoothly. Key components like jaw plates, bearings, and flywheels should be checked for signs of wear. For example:

● Inspect jaw plates for cracks or excessive wear.

● Ensure bearings are lubricated and free from debris.

● Check flywheels for any imbalances or cracks.

Identifying problems early can prevent breakdowns and costly repairs.

Over time, parts like jaw plates, toggle plates, and bearings will wear out and need replacing. It's important to:

● Replace jaw plates once they become too worn to function efficiently.

● Ensure toggle plates are in good condition to maintain crushing pressure.

● Replace bearings to avoid unexpected failures.

Always use high-quality replacement parts to ensure the crusher continues to perform optimally.

Maintenance Task | Recommended Action | Key Parts to Inspect |

Jaw Plate Inspection | Replace if cracked or excessively worn | Jaw plates, cheek plates |

Bearing Inspection | Lubricate regularly, replace if worn | Bearings, eccentric shaft |

Flywheel Check | Look for cracks or imbalances, replace if necessary | Flywheel, drive motor |

Toggle Plate Inspection | Replace if damaged or excessively worn | Toggle plates, pitman |

Lubrication Check | Apply grease or oil as needed | Bearings, eccentric shaft, pitman |

Jaw crushers are subject to wear and tear due to continuous operation. The most commonly affected parts are the jaw plates and toggle plates. Over time, the jaw plates can become worn down, affecting their ability to crush effectively. As the plates wear, the crushing efficiency decreases, leading to higher energy consumption and more frequent maintenance.

Toggle plates can also experience wear, which may cause misalignment or reduce crushing force. Regular inspection is essential to detect signs of wear and prevent breakdowns.

Cracks in the frame, flywheel, or eccentric shaft can cause severe damage to the crusher. The frame should be checked regularly for any signs of stress or cracking, especially around areas that experience high pressure. Flywheels can develop cracks due to excessive strain during operation.

The eccentric shaft, which plays a key role in generating motion, is susceptible to cracking as well. Regularly inspecting these parts can help identify potential issues early, preventing catastrophic failure.

Common Issue | Affected Parts | Prevention Tip |

Wear on Jaw Plates | Jaw plates, toggle plates | Regular inspection, replace worn parts early |

Cracks in Frame | Frame, flywheel | Inspect for cracks, ensure proper support |

Eccentric Shaft Issues | Eccentric shaft, bearings | Regular checks and lubrication |

Wear on Toggle Plates | Toggle plates | Inspect for wear, replace when necessary |

Each jaw crusher part plays a vital role in its operation. Understanding these parts ensures the crusher works efficiently and lasts longer. Regular maintenance helps minimize downtime and reduces repair costs.

A: The main parts of a jaw crusher include the drive motor, flywheel, eccentric shaft, pitman, toggle plates, and jaw plates.

A: The flywheel helps generate momentum, carrying the jaw through the crushing cycle and ensuring smooth operation by maintaining energy.

A: Jaw plates should be replaced when they show significant wear, especially at the bottom, where crushing pressure is highest.

A: Regular maintenance, proper lubrication, and ensuring the correct feed material size can help prevent excessive wear.

A: Signs include excessive vibration, noise, or a decrease in performance. Bearings should be regularly checked to ensure they function smoothly.