- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

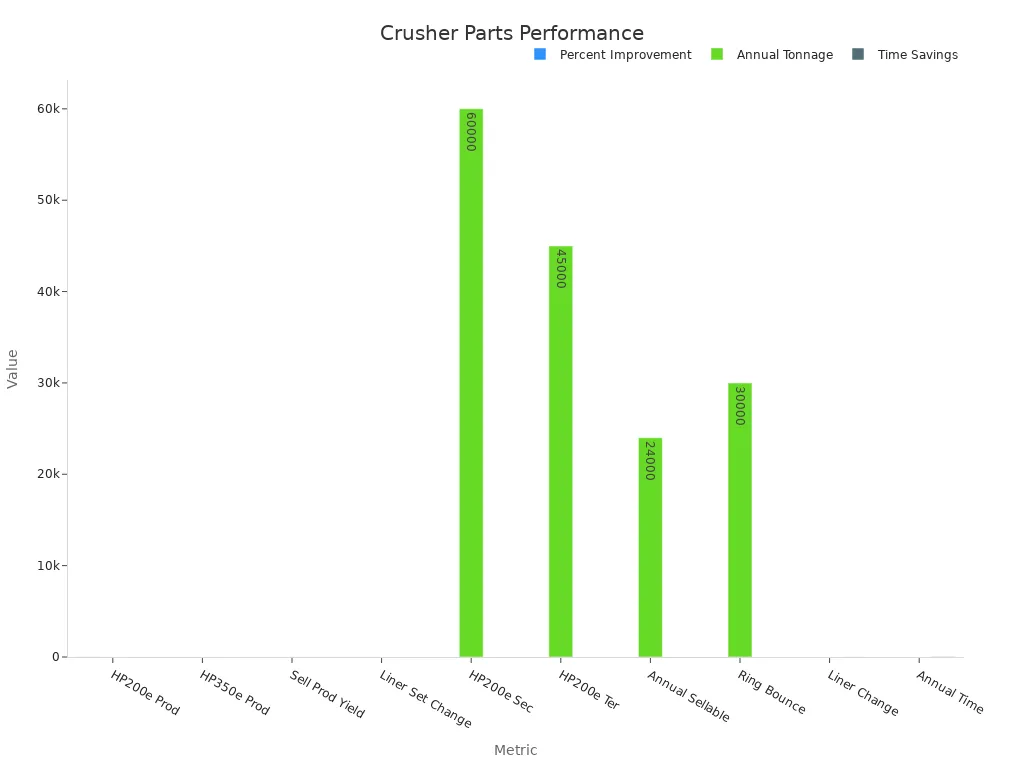

Crushers are machines that break down large rocks or materials into smaller pieces, making them essential in mining and construction. You need to choose the right types of crushers for your distinctive needs because material hardness and desired product size affect efficiency and output. Using high-quality crusher parts, such as wear-resistant liners and mantles, can boost your crushing equipment’s performance and lifespan. For example, optimizing your crusher parts and matching them to your application can increase throughput by up to 22% and extend liner life by up to 40%.

| Performance Metric | Numerical Data | Explanation |

|---|---|---|

| Production Increase (HP200e) | Up to 20% more production | Efficient chamber design and parts |

| Liner Life Extension | 5-10% reduction in replacements | High-quality wear parts reduce downtime |

Choose the right crusher type based on your material hardness, desired product size, and application to improve efficiency and equipment life.

Jaw crushers work best for large, tough materials and primary crushing, while cone and impact crushers suit secondary and tertiary stages for finer, uniform products.

High-quality wear parts boost crusher performance, reduce downtime, and extend the life of your equipment across all crusher types.

Impact crushers produce cubical-shaped aggregates ideal for construction, and gyratory crushers handle large capacities in mining with continuous operation.

Test your material and project needs carefully, and consult trusted suppliers to select crushers and parts that match your specific goals and improve productivity.

When you choose crushing equipment, you need to understand the different types of crushers and how they work. Each crusher type has a unique design and purpose. Selecting the right one helps you achieve the best results for your material and application. Hunan Xiangjian Machinery Technology Co., Ltd. manufactures high-quality wear parts for all these crusher types, ensuring reliable performance and long service life.

Jaw crushers use a fixed jaw and a moving jaw to crush large rocks into smaller pieces. You feed material into the top of the machine. The moving jaw presses the material against the fixed jaw, breaking it down by compression. This type of crusher is popular for primary crushing because it handles large feed sizes and tough materials.

| Jaw Crusher Segment | Statistic / Efficiency Detail | Notes / Impact |

|---|---|---|

| Single Toggle Jaw Crushers | Largest market share in 2024; simpler design reduces maintenance | Lower downtime and operational costs |

| Capacity 100–300 TPH | Holds 44.8% market share; balance of capacity and cost efficiency | Popular in infrastructure and construction |

| IoT and AI Integration | Enables real-time supervision and predictive maintenance | Minimizes downtime and operational costs |

| Fuel Efficiency | Optimized for reduced fuel consumption and emissions | Supports sustainability initiatives |

You often see jaw crushers in mining and construction because they accept large boulders and reduce the need for extra drilling or blasting. Hunan Xiangjian Machinery Technology Co., Ltd. supplies durable jaw plates and liners for these machines.

Cone crushers use a rotating cone inside a fixed bowl to crush material. The material enters the top and gets squeezed between the cone and the bowl liner. This action breaks the material into smaller pieces. You can adjust the crusher setting to control the size of the output.

Cone crushers work well for secondary and tertiary crushing.

They produce finer material than jaw crushers.

Automatic setting controls and hydraulic systems improve efficiency and product quality.

You benefit from cone crushers when you need high capacity and precise product size. Hunan Xiangjian Machinery Technology Co., Ltd. offers mantles, concaves, and bowl liners made from wear-resistant manganese steel for these crushers.

Tip: Choke feeding cone crushers helps you get better product shape and reduces operating costs.

Impact crushers use high-speed impact to break down materials. You feed material into a chamber where a rotor spins rapidly. The rotor hurls the material against impact plates, shattering it into smaller pieces. There are two main types: horizontal shaft impact (HSI) and vertical shaft impact (VSI) crushers.

| Aspect | Evidence Summary | Impact/Result |

|---|---|---|

| Production Efficiency | VSI crushers can boost aggregate production efficiency by up to 30% compared to traditional crushers. | Significant increase in throughput and operational productivity. |

| Product Quality | VSI crushers produce more consistent, cubical-shaped aggregates, improving material quality. | Enhanced aggregate shape and size uniformity, crucial for construction applications. |

| Waste Reduction | VSI technology minimizes over-crushing and reduces unusable aggregate waste by about 25%. | More sustainable production with less raw material waste and landfill impact. |

| Maintenance and Durability | Use of high wear-resistant materials and patented designs extend service life by 30%-200%. | Reduced maintenance costs and downtime, improving overall operational efficiency. |

You should use impact crushers when you want a cubical product and high throughput. Hunan Xiangjian Machinery Technology Co., Ltd. provides robust blow bars and impact plates for both HSI and VSI crushers.

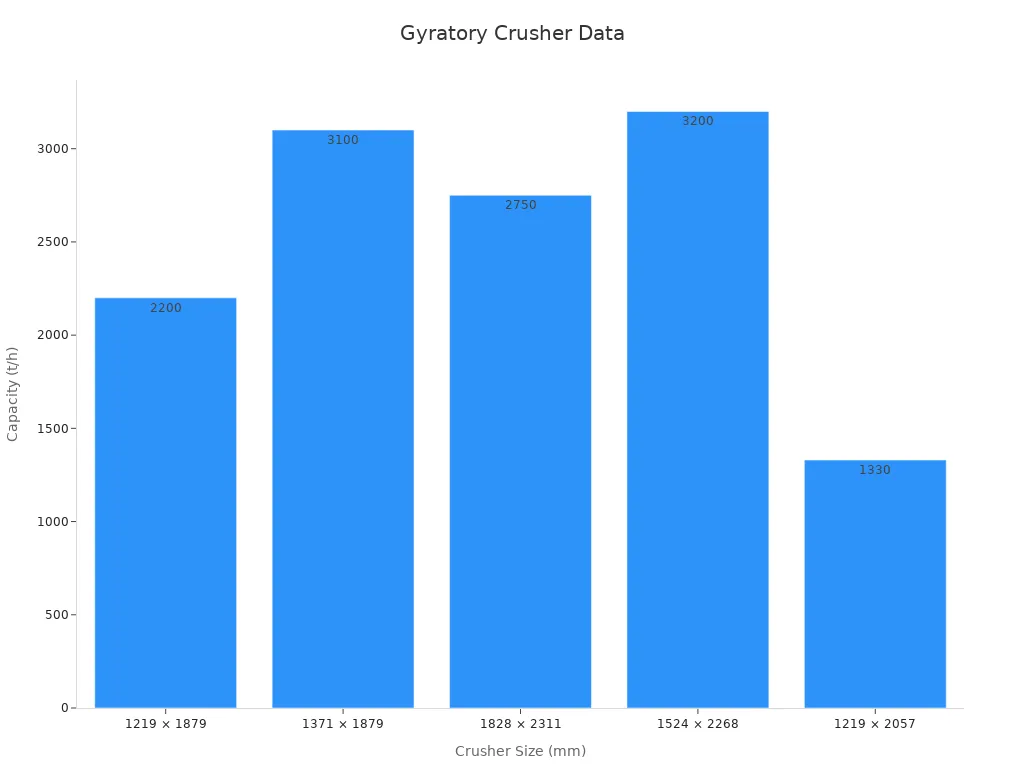

Gyratory crushers have a large, heavy cone that moves within a bowl. The material enters the top and gets crushed as the cone oscillates. This type of crusher works continuously, unlike jaw crushers, which operate in batches.

| Gyratory Crusher Size (Gape × Mantle Diameter, mm) | Capacity (tons per hour) | Comparative Throughput Factor vs Jaw Crushers |

|---|---|---|

| 1219 × 1879 | 2200 t/h | ~2.5 to 3 times higher than jaw crushers of same gape |

| 1371 × 1879 | 3100 t/h | - |

| 1828 × 2311 | 2750 t/h | - |

| 1524 × 2268 | 3200 t/h | - |

| 1219 × 2057 | 1330 t/h | - |

You find gyratory crushers in large mining operations because they handle high capacities and continuous operation. Hunan Xiangjian Machinery Technology Co., Ltd. produces mantles and concaves for these powerful machines.

Hammer crushers use rotating hammers to strike and shatter material. The material enters a chamber and gets hit by the fast-moving hammers, breaking it into smaller pieces. This type of crusher is versatile and works well for soft to medium-hard materials like limestone, coal, and gypsum.

| Metric Category | Verified Metrics / Insights |

|---|---|

| Market Size (2022) | Approximately USD 2.3 billion |

| Projected Market Size (2030) | USD 3.5 billion |

| CAGR (2022-2030) | Around 5.6% |

| Key Applications | Cement Industry: 35%, Glass: 20%, Refractory Materials: 15% |

| Benefits | Versatile crushing of coal, gypsum, limestone; automation and energy-efficient mechanisms improve operational efficiency and reduce costs; critical in mining, construction, metallurgy |

You can use hammer crushers in cement, glass, and recycling industries. Hunan Xiangjian Machinery Technology Co., Ltd. supplies high-manganese hammers and liners for these crushers.

Roll crushers use two rotating cylinders to crush material between them. The gap between the rolls determines the final product size. You feed material into the top, and the rolls pull it through, breaking it down by compression and shear.

Roll crushers produce very consistent particle sizes.

They work well for medium to fine crushing of softer materials.

The constant gap between the rolls allows you to control product size precisely.

Studies show that roll crushers deliver more uniform particle sizes than jaw crushers. This makes them ideal when you need strict control over the final product. Hunan Xiangjian Machinery Technology Co., Ltd. manufactures wear-resistant roll shells and liners for these crushers.

Note: You can rely on Hunan Xiangjian Machinery Technology Co., Ltd. for wear parts for all these different kinds of crushers, ensuring your equipment stays productive and efficient.

Choosing the right crushers depends on your distinctive needs. You must consider the hardness of the material, the desired product size, and the specific application. Each of these factors affects how you approach material processing and which types of crushers you select.

Material hardness plays a key role in crusher selection. Harder materials cause more wear on crusher parts and require stronger machines. For example, when you process plastics with different hardness levels, you see that jaw crushers use compression, hammer crushers use impact, and cone crushers offer adjustable settings. The table below shows how material hardness and crusher types relate:

| Material (Plastic Type) | Hardness (Shore D) | Crusher Type Used | Crushing Mechanism | Typical Application Stage |

|---|---|---|---|---|

| PMMA | 67.7 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

| PP | 68.2 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

| PA-6 | 69.5 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

| ABS | 71.3 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

| PC | 76.1 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

| PS | 78.9 | Hammer, Jaw, Cone | Impact, Compression, Adjustable | First and Second Stage |

Studies show that as the hardness of the material increases, the erosion and wear on crusher parts also rise. You need to match the hardness of your material with the right crusher and wear parts to reduce the size of rocks efficiently and extend equipment life.

You must decide what final size you want for your material. Some crushers, like cone crushers, let you adjust the output size easily. If you need fine material for recycling used building materials or for making road base, you might choose cone or impact crushers. For larger, rougher pieces, jaw crushers work well. The right product size helps you meet project requirements and improves material processing.

Your application determines which types of crushers you need. In mining, you often use jaw crushers for primary crushing rocks and stones, then switch to cone or impact crushers for secondary stages. In construction, you might focus on recycling used building materials or crushing old concrete and asphalt. Each scenario requires different types of crushers and wear parts. For example, hammer crushers handle softer materials in cement plants, while roll crushers work well for fine material processing in recycling facilities.

Tip: Always match your crusher types to the various types of materials and the specific job, whether you are working in mining, construction, or recycling.

Crushing operations usually happen in three main stages: primary, secondary, and tertiary. Each stage uses specific types of crushers to reduce material size and improve product quality. Choosing the right crusher for each stage helps you get the best results and extends the life of your equipment.

You start with primary crushers to handle large, raw materials straight from the mine or quarry. Jaw crushers and gyratory crushers work best at this stage. They use compressive force to break down big rocks into smaller, manageable pieces. For example, jaw crushers can take feed sizes up to 1400 mm and reduce them to about 200–300 mm. Gyratory crushers can handle even larger feed sizes, up to 1500 mm, and offer high capacity, sometimes over 5000 tons per hour. These machines set the foundation for the next steps in the process.

| Crusher Type | Max Feed Size (mm) | Typical Product Size (mm) | Typical Capacity (t/h) |

|---|---|---|---|

| Jaw Crusher | Up to 1400 | 200–300 | Up to 1600 |

| Gyratory Crusher | Up to 1500 | 200–300 | 1200 to 5000+ |

| Horizontal Impact | Up to 1300 | 200–300 | Up to 1800 |

Tip: Using high-quality wear parts, like those from Hunan Xiangjian Machinery Technology Co., Ltd., helps your primary crushers last longer and perform better.

After the primary stage, you use secondary crushers to further reduce the material size. Cone crushers and horizontal-shaft impact crushers are common choices here. These machines refine the product, often reducing sizes from 300–100 mm down to 100–38 mm. Cone crushers use a rotating mantle to apply pressure, creating graded materials ideal for road base and construction. Secondary crushers also let you adjust settings for better control over product size and shape.

Secondary crushers improve product quality by producing more uniform and cubical shapes.

Features like hydraulic gap adjustment and choke feeding help you maintain consistent output.

Screening between stages ensures only the right-sized material moves forward.

Tertiary crushers handle the final reduction, producing fine aggregates around 12 mm or less. Vertical shaft impactors (VSIs) and some cone crushers excel at this stage. VSIs create cubical-shaped sand, which is important for high-quality concrete and asphalt. When you optimize feed distribution and use the right wear parts, you can boost throughput and achieve a more uniform product. Studies show that improved feed design in tertiary cone crushers can increase throughput by 36% and create a finer, more consistent product.

Note: Always match your wear parts to the demands of each stage. This practice keeps your crushers efficient and extends their service life.

You want your crushing equipment to work efficiently and save energy. Different crushers perform better in different situations. Jaw crushers handle large feed sizes and offer high production capacity with lower energy use. Cone crushers work well for secondary and tertiary stages, producing more uniform products but using more energy. The table below shows how these two types compare:

| Aspect | Jaw Crusher | Cone Crusher |

|---|---|---|

| Feed Size Capacity | Up to 1500 mm | Up to 350 mm |

| Production Capacity | 200-1000 tons/hour | 100-750 tons/hour |

| Energy Consumption | 1-2 kWh/ton | 2-4 kWh/ton |

| Maintenance | Simpler, lower complexity | More complex, longer wear part life |

| Initial Investment | Lower | Higher |

| Noise Level | Louder | Quieter |

| Dust Generation | More dust | Finer dust, less quantity |

| Product Gradation | Wider range | More uniform, cubical |

Impact crushers often use less energy than cone crushers because they break material with impact forces. You can also improve efficiency by choosing high-quality wear parts. For example, manganese steel liners from Hunan Xiangjian Machinery Technology Co., Ltd. last longer and help reduce downtime.

Tip: Regular inspection and proper installation of wear parts keep your crushers running smoothly and efficiently.

The shape of your final product matters, especially for construction and road projects. Impact crushers produce more cubical and angular aggregates, which are ideal for concrete and asphalt. Cone crushers and jaw crushers create different shapes, with cone crushers making more uniform and rounded particles. Quality tests like the Aggregate Image Measurement System (AIMS) and Fine Aggregate Angularity (FAA) show that crusher type changes the angularity and texture of your product. You should choose the right crusher based on the shape you need for your project.

Not all crushers work well with every material. Jaw crushers and roll crushers handle hard, brittle rocks best. Cone crushers suit medium-hard to hard materials, especially when you need precise control over product size. Impact crushers excel with softer or less abrasive materials and produce high-quality, cubical aggregates. Empirical studies show that you should test your material’s hardness and work index before choosing a crusher. Matching the right crusher to your material ensures better performance and longer equipment life.

Note: High-quality wear parts from Hunan Xiangjian Machinery Technology Co., Ltd. help you process tough materials and keep your crushing equipment reliable.

When you make a choice of the crusher, you need to look at several important factors. Each project has unique requirements, so you must match your equipment to your goals. Here are some key points to consider:

Type of material you want to process. Hard rocks, soft minerals, and recycled materials each need different crushers.

Crushing capacity. Higher capacity means more material processed in less time.

Maintenance and durability. Reliable machines reduce downtime and keep your operation running smoothly.

Energy consumption. Efficient crushers save money and help the environment.

Safety and ergonomic design. Safe equipment protects workers and improves reliability.

After-sales support. Good support ensures your equipment stays in top shape.

Total cost of ownership. Look at both the purchase price and long-term operating costs.

Industry trends and new technology. Updated equipment can improve performance and safety.

| Factor Category | Details and Impact |

|---|---|

| Crusher Type | Each type fits specific materials and workloads. |

| Material Processed | The nature of your material affects wear and durability. |

| Operating Conditions | Mining and construction need robust machines. |

| Technological Advances | New designs improve wear resistance and safety. |

| Operational Factors | Maintenance, energy use, and support affect efficiency. |

Tip: Always review your project needs before selecting crushing equipment. This step helps you avoid costly mistakes.

You can use practical strategies to make the best decision. Start by testing your material’s hardness and size. Use models and simulations to predict output and product shape. For example, engineers use empirical models and full-scale tests to optimize cone crusher settings. These methods help you get the right particle size and shape for your project.

Advanced control systems, such as machine learning and predictive controls, also improve crusher performance. Simulation-driven optimization can boost productivity by over 30% and lower energy use. You should always consult with experts or trusted suppliers like Hunan Xiangjian Machinery Technology Co., Ltd. They can help you choose the right parts and settings for your specific needs.

Note: A good supplier will offer tailored solutions, reliable after-sales support, and high-quality wear parts. This support keeps your crushers running efficiently and extends their service life.

Understanding the right equipment for your project leads to better results and longer-lasting machinery.

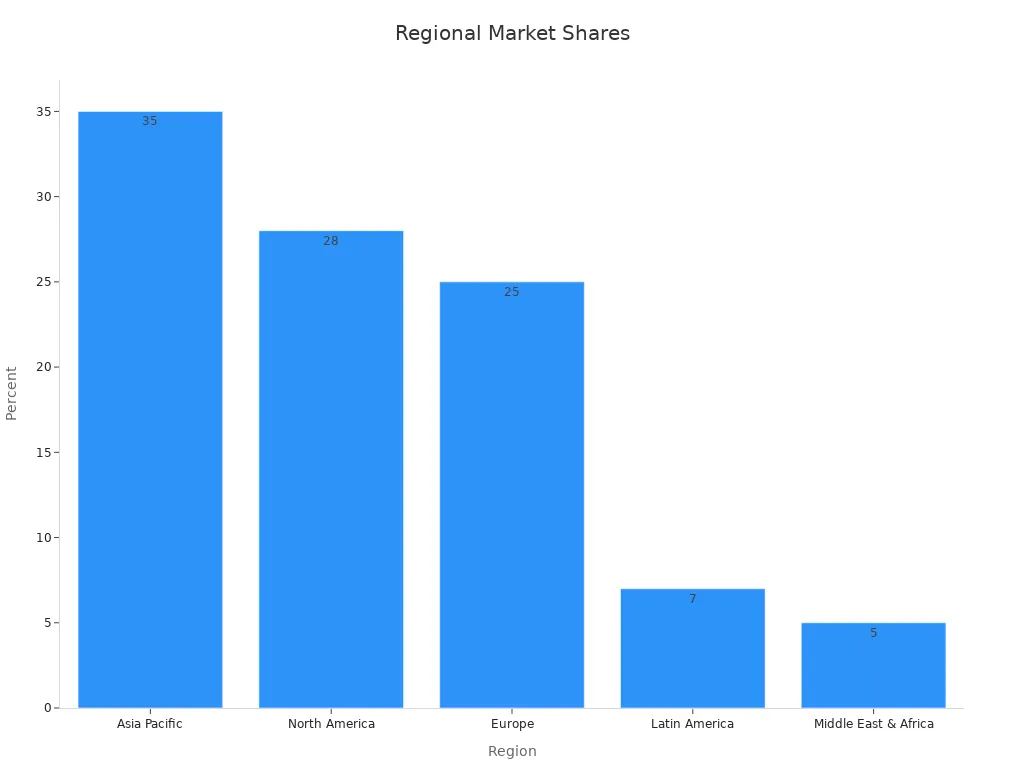

Impact models excel in recycling because they deliver high reduction ratios and meet environmental standards.

Gyratory types dominate mining for their capacity and efficiency.

Hammer designs suit cement manufacturing, producing finer materials.

Market trends show that automation, mobility, and energy-efficient options help you match equipment to your specific needs.

For the best outcome, always consider your material, application, and the quality of wear parts. Reach out to trusted suppliers for expert guidance.

You will find different types of crushers such as jaw, cone, impact, gyratory, hammer, and roll crushers. Each crusher type works best for specific materials and applications. You should match the crusher to your distinctive needs for efficient material processing.

You should consider the hardness of your material, the desired product size, and your application. The choice of the crusher depends on whether you are crushing rocks and stones, recycling used building materials, or crushing old concrete and asphalt.

Product shape affects the quality of your final material. Impact crushers produce cubical shapes, which are ideal for construction. Cone crushers and other types create different shapes. You should select the right crusher types to meet your project requirements.

You can use some crushing equipment for different kinds of crushers, but not all machines suit every material. You should always check if your equipment can reduce the size of rocks or handle your specific material processing needs.

Wear parts help your crushers last longer and work better. High-quality parts reduce downtime and improve efficiency. You should replace worn parts regularly to keep your crushing equipment running smoothly during all stages of crushing operations.