- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

You may wonder, what is a crusher and what is a crusher used for in today’s industries? An impact crusher breaks down materials using high-speed hammers and impact plates, not compression like other crushers. You will see impact crushers produce uniform grain sizes and handle a variety of materials, from concrete rubble to limestone. This makes them stand out when you ask what is a crusher used for in material processing. If you need consistent particle size and high production, impact crusher functions deliver reliable results.

Impact crushers break materials using high-speed hammers and impact plates, producing uniform particle sizes ideal for construction and recycling.

You can adjust the crusher settings to control the size and shape of the final product, making impact crushers flexible for different needs.

These crushers work well with medium to soft materials like limestone, concrete, and asphalt, supporting industries like mining, construction, and recycling.

There are two main types: horizontal shaft impactors (HSI) for large feed and high reduction, and vertical shaft impactors (VSI) for fine, cubical aggregates.

Impact crushers offer benefits like high capacity, low power use, easy maintenance, and cost savings, but require regular wear part replacement to keep running smoothly.

When you explore the world of crushing machines, you will notice that impact crushers stand out for their unique way of breaking down materials. Instead of squeezing rocks like some other crushers, an impact crusher uses high-speed rotating hammers or blow bars to strike the material. The material enters the crushing chamber and meets these fast-moving parts. The force of the impact shatters the material, sending it against sturdy impact plates or breaker blocks. This action repeats until the pieces reach the right size and exit the machine.

You can think of the process as a series of quick, powerful hits. The hammers, often made from tough manganese steel, spin at speeds of 250 to 400 rpm. They can weigh anywhere from 20 to 200 kg. The rim speed can reach up to 50 meters per second. This high energy ensures efficient size reduction, making the impact crusher a reliable size reduction machine for many industries.

The design of these crushers allows you to adjust the gap between the hammers and the impact plates. This adjustment lets you control the final particle size. If you want finer material, you can set a smaller gap. If you need larger pieces, you can widen the gap. This flexibility makes impact crushers valuable in different crushing operations and at various crushing stages.

Recent studies and market reports highlight the efficiency of impact crushers. For example, modern models often include automation and remote monitoring. These features help you track throughput, power use, and particle size distribution. Machine learning and sensor technology can optimize the crushing process, making your operations more energy-efficient and productive. Research also shows that when you operate these machines with the right feed size and settings, you can achieve high throughput and uniform product size.

Note: Understanding crushing stages is important. Impact crushers often work best in secondary or tertiary roles, where you need to produce consistent, high-quality aggregates.

To fully grasp how impact crushers work, you should know the main parts that make up these powerful size reduction machines. Each component plays a specific role in the crushing process:

Rotor: This is the heart of the impact crusher. The rotor spins at high speed and carries the hammers or blow bars. A larger rotor increases inertia, which boosts throughput and improves efficiency.

Blow Bars/Hammers: These heavy-duty parts attach to the rotor. They deliver the main impact force that breaks down the material. Manufacturers often use manganese steel or high-chromium alloys for extra durability.

Impact Plates/Breaker Blocks: After the initial impact, the material hits these solid surfaces. The plates further reduce the size of the material by crushing it against a hard surface.

Aprons: You can adjust these to control the output size or to compensate for wear. This adjustment helps you maintain consistent product quality.

Feed Opening: This is where you load the material. The size of the feed opening determines the maximum size of material the crusher can handle.

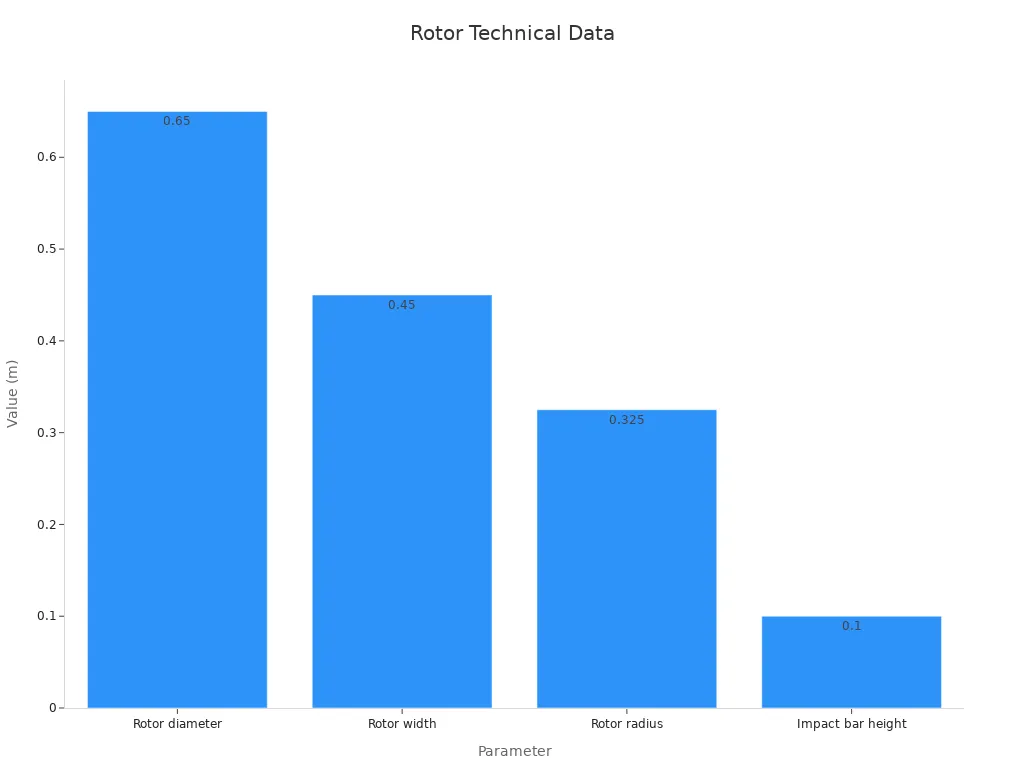

Here is a table showing some typical technical parameters for impact crushers:

| Parameter | Value | Description/Notes |

|---|---|---|

| Rotor diameter | 0.65 m | Diameter of the crusher rotor |

| Rotor width | 0.45 m | Width of the rotor |

| Rotor radius | 0.325 m | Half of rotor diameter |

| Impact bar height | 0.1 m | Height of the rotor’s impact bars |

| Feed size range | 14 to 20 mm | Calibrated feed particle size |

You can see how these parameters affect the performance of your crushing equipment. For example, a larger rotor and feed opening allow you to process bigger rocks and increase capacity. Some models can handle feed sizes up to 650 mm and reach production capacities of 400 tons per hour. Power requirements can range from 200 to 300 kW, depending on the model.

When you select an impact crusher, pay attention to these technical details. They help you match the right crushing equipment to your needs, whether you work in mining, construction, or recycling. Understanding impact crushers and their key components gives you the knowledge to optimize your crushing operations and achieve the best results.

You will find impact crushers in almost every major construction and infrastructure project. These machines play a key role in producing aggregate for construction, such as sand, gravel, and crushed stone. You often see them in quarries, where they break down granite, limestone, and basalt into uniform sizes. This process supports the building of roads, bridges, and high-speed railways. Impact crusher usage is especially common in highway aggregate production lines because of their large crushing ratio and ability to deliver consistent particle size.

Impact crushers help drive economic growth by supporting large-scale projects. The market for these crushers reached $1.5 billion in 2024 and is expected to grow rapidly as demand for aggregate crushing rises worldwide.

You can rely on impact crushers for their efficiency and lower power consumption compared to traditional crushing equipment. Their wide range of applications includes the cement industry, where they process raw materials like limestone and clay. When you need reliable performance and durable parts, companies like Hunan Xiangjian Machinery Technology Co., Ltd. supply high-quality wear parts to keep your crushers running smoothly.

Typical materials processed:

Granite

Limestone

Basalt

Sandstone

Concrete

You will also see impact crushers at the center of recycling concrete and asphalt. These machines handle demolition and construction waste recycling by breaking down old structures into reusable materials. This supports sustainability and reduces landfill waste. In recycling plants, impact crushers process concrete, asphalt, and even glass, turning them into valuable aggregates for new projects.

In mining operations, you use impact crushers to process medium-hard materials like limestone and ore. These crushers withstand harsh conditions and deliver reliable results. Studies show that impact crushers produce aggregates with good shape and size, making them ideal for both construction and road engineering. When you choose the right crushing equipment, you improve efficiency and extend the life of your operation.

Tip: For the best results in demanding environments, select wear parts from trusted suppliers like Hunan Xiangjian Machinery Technology Co., Ltd. Their products help you maintain continuous production and reduce downtime.

The uses of impact crushers span a wide range of applications, from aggregate production to recycling and mining. You benefit from their ability to handle different materials and deliver consistent results.

When you look at the types of crushers used in material processing, you will find two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). Each type offers unique features and benefits for different applications.

You will see horizontal shaft impactors in many industries, including mining, construction, and recycling. These impact crushers use a horizontal rotor that spins at high speed. The material enters the crusher and meets the blow bars attached to the rotor. The impact breaks the material and sends it against fixed plates for further reduction.

HSI crushers handle a wide range of feed sizes and deliver high reduction ratios. You can choose models with capacities below 100 TPH for small projects, 100-300 TPH for medium jobs, and above 300 TPH for large-scale operations. For example, the CI731 HSI impact crusher can process feed up to 1000 mm and reach capacities of 400-700 TPH. Many modern HSI crushers include digital automation, remote monitoring, and predictive maintenance. These features help you reduce downtime and improve reliability. You also benefit from modular designs that make maintenance easier and safer.

Tip: Hunan Xiangjian Machinery Technology Co., Ltd. provides durable wear parts for horizontal shaft impactors, helping you extend the life of your equipment.

Vertical shaft impactors use a different approach. In these impact crushers, the rotor stands upright. Material drops into the center of the rotor and gets thrown outward at high speed. The impact with the anvils or rock shelves crushes the material into fine, cubical particles.

VSI crushers excel at producing high-quality sand and aggregates. You will notice that these machines create more isometric and tougher particles, which are ideal for concrete and road construction. Studies show that VSI crushers use less energy and require less space than other crushers. You can adjust the feed rate and rotor speed to control the final product size and shape. However, VSI crushers may produce more stone powder, so you should consider dust control solutions.

| Aspect | HSI (Horizontal Shaft) | VSI (Vertical Shaft) |

|---|---|---|

| Rotor Orientation | Horizontal | Vertical |

| Best For | Large feed, high reduction ratio | Cubical particles, fine aggregates |

| Typical Applications | Mining, recycling, construction | Sand making, concrete, road base |

| Particle Shape | Good | Excellent |

| Energy Efficiency | High | Higher |

Note: Hunan Xiangjian Machinery Technology Co., Ltd. supplies wear parts for both types of impact crushers, ensuring reliable performance in any application.

When you choose an impact crusher, you gain several important benefits that help your operation run smoothly. These machines stand out for their light weight and compact size, making them easy to install and move. You can achieve a high reduction rate, which means you break down large materials into smaller pieces quickly and efficiently. This leads to great quality end products with uniform particle size, which is essential for construction and road projects.

You will also notice that impact crushers offer selective crushing. This means you can control the size and shape of the final product by adjusting the machine settings. The simple structure of these crushers makes maintenance easier and reduces downtime. You save on energy costs because impact crushers use less power compared to other types of crushers. Many industries, such as mining, construction, and recycling, rely on these machines for their high capacity and cost savings.

Note: Recent research shows that impact crushers can serve as both primary and secondary crushers. Their versatility and ease of maintenance increase productivity and reduce downtime across different applications.

Here is a table summarizing the main advantages of impact crushers:

| Advantage | Description |

|---|---|

| Light weight | Easy to transport and install |

| High capacity | Handles large volumes of material |

| Uniform particle size | Consistent, high-quality output |

| Selective crushing | Adjustable settings for desired product shape |

| Low power consumption | Reduces energy costs |

| Simple structure | Easier maintenance and lower downtime |

| Cost savings | Lower operational and maintenance expenses |

While impact crushers offer many benefits, you should also consider some limitations. The main disadvantages of impact crushers involve wear and maintenance. The blow bars and impact plates experience significant wear due to high-speed impacts. You need to replace these parts regularly, which can increase maintenance costs.

Rotor wear is another challenge. Using wear-resistant materials and regular inspections can help extend the life of these components. If you process very hard or abrasive materials, you may see faster wear and more frequent maintenance. Managing the size and type of material you feed into the crusher helps prevent blockages and unplanned downtime.

Tip: Regular maintenance and the use of high-quality wear parts can reduce downtime and improve reliability. Digital monitoring systems now help you track wear and schedule preventive maintenance, making your operation more efficient.

Recent studies highlight that process conditions—such as feed size, material hardness, and rotor speed—affect the performance and maintenance needs of your impact crusher. By understanding these factors, you can maximize productivity and minimize costs.

When you look at the types of crushers available, you will notice that jaw crushers and impact crushers serve different roles in material processing. Jaw crushers act as the primary and secondary crusher for hard, abrasive materials like granite and basalt. They use compression to break down large rocks, producing a wide range of particle sizes. You often see jaw crushers at the start of a crushing circuit because they handle bigger feed sizes and higher capacities.

Impact crushers, on the other hand, use high-speed impact to break materials. You will find them most effective for medium to soft materials such as limestone, gypsum, and recycled concrete. These machines produce more cubical and uniform particles, which are ideal for road construction and concrete production. When comparing impact crushers to jaw crushers, you should consider the shape of the final product. Jaw crushers tend to create elongated and flaky particles, while impact crushers deliver a more consistent, cubical shape.

Here is a quick comparison:

| Feature | Impact Crusher | Jaw Crusher |

|---|---|---|

| Operating Principle | High-speed impact | Compression between two jaws |

| Material Suitability | Medium to soft materials | Hard, abrasive materials |

| Output Quality | Cubical, uniform particles | Varied sizes, less uniform |

| Application | Secondary/tertiary crushing, recycling | Primary crushing, mining, quarrying |

| Maintenance | Skilled, less frequent | Simpler, more frequent |

| Cost | Higher wear and maintenance | Lower initial investment |

Tip: Matching the right crusher to your material and project needs helps you optimize performance and reduce costs.

When comparing impact crushers with cone crushers, you will see more differences in how they process materials and the results they deliver. Cone crushers work best with medium to hard materials and use compression to create fine, angular aggregates. You often use cone crushers for secondary or tertiary crushing in mining and aggregate plants.

Impact crushers, especially vertical shaft types of crushers, produce more cubical and less flaky particles. This makes them a top choice for applications where particle shape matters, such as in concrete or asphalt production. Cone crushers require a consistent feed size and produce aggregates with more angularity and flakiness. Impact crushers, by contrast, handle a wider range of feed sizes and deliver better particle shape.

Wear parts play a big role in both types of crushers. You need to choose high-quality wear parts to keep your equipment running efficiently. Companies like Hunan Xiangjian Machinery Technology Co., Ltd. supply durable wear parts for all types of crushers, helping you reduce downtime and maintenance costs.

Key points when comparing impact crushers and cone crushers:

Impact crushers excel at producing cubical particles from softer materials.

Cone crushers are better for hard, abrasive materials and deliver fine, angular aggregates.

The choice depends on your desired output, material type, and cost considerations.

Remember: Selecting the right types of crushers for your operation ensures you get the best performance, product quality, and cost-effectiveness.

You now understand that an impact crusher delivers efficient size reduction and produces uniform particles for many industries. Choose this machine when you need high-quality aggregates, especially for construction or recycling. Consider your material type, project scale, and the value of durable wear parts.

Market trends show rising demand for impact crushers in mining, construction, and recycling.

Automation and sustainability drive new technology and efficiency.

Asia Pacific leads growth, with North America and Europe following.

Explore more about crusher types and maintenance to make the best choice for your operation.

You can process many materials, such as limestone, concrete, asphalt, and glass. Impact crushers work well with medium-hard and soft materials. You often use them in construction, mining, and recycling projects.

You should check wear parts like blow bars and impact plates often. Replace them when needed. Clean the machine regularly. Follow the manufacturer's maintenance schedule to keep your crusher running smoothly.

A stationary impact crusher stays in one place. You use it for fixed plants. A mobile impact crusher moves easily between sites. You can use it for projects that need flexibility or quick setup.

You should consider the type of material, required output size, and production capacity. Think about your site conditions and budget. Talk to equipment suppliers for advice on the best model for your needs.

Good particle shape helps make strong concrete and smooth roads. Impact crushers produce cubical particles. This shape improves the quality of your final product and meets industry standards.